I suppose the first thing to address is: is Bettering a pretend word?

I don’t know, I get it, and I bet you do. So we are all good.

This tale is about the bettering of Alhambra’s Bow Bedroom.

Not unusual on a boat are nasty termite annoyances. Sadly the Bow Bedroom became a mild casualty of termite lunacy.

A project to end the termite and repair the resulting damage began.

Naturally, this starts with termite extermination.

Thanks to Pest Guy and a nine-month plan, we have been able to stop the colony’s wood-eating frenzy.

Termite dining damaged wooden support structures underneath the Bow Port room floorboards. The feasting had also eaten away at the storage cabinet’s lower surface.

Though not massive damage, it was enough to become quite the challenge.

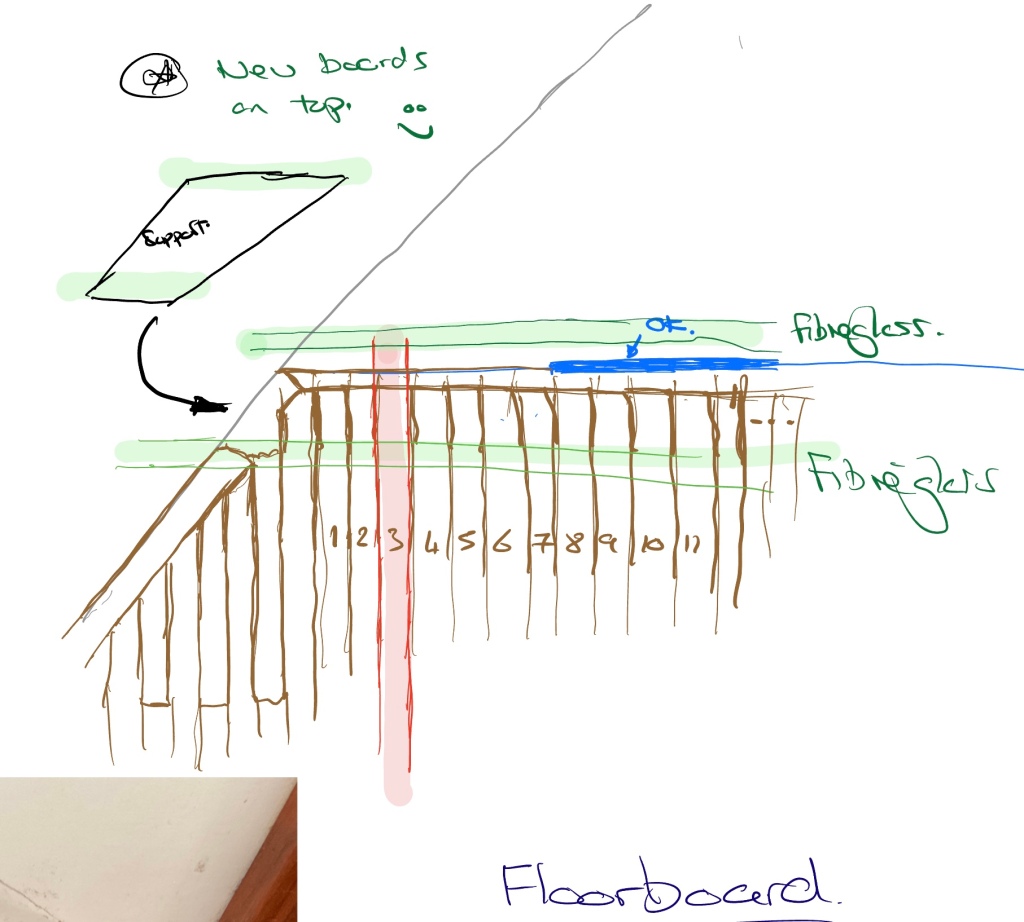

To help clarify my path forward I crafted a few repair sketches – thanks Noteability.

In addition to repairing the floor and wall the hull storage underneath the Bow bedroom required a tidy up.

We rearranged the stored content into 15 plastic storage boxes. Each with dehumidifying bags stashed inside.

Much better.

No longer weak 🙂

With the hole in the port side wall filled with fibreglass, sanded and repainted and the replacement underfloor support timber sealed firmly in place. It became time for new floorboard sections to be crafted and placed.

Painted, sealed and ready for new floorboards to be cut and placed.

Exciting to have the floor restored to a stable condition.

The termites had actually eaten the original boards.

Sun Hing Shing.

SO thankful to Eric from SHS.

I am pleased to show that the boards were cut, placed and varnished with three coats of International varnish / Satin finish.

It’s good to know that the corner section of the room has been returned to a quality level.

With that done it is time to move onto the room lighting, curtains and window sealant.

The grey flakiness of the sun hammered varnish is the sign to get the old Makita Orbital out again. Not that it had been put away at all…

The grey flakiness of the sun hammered varnish is the sign to get the old Makita Orbital out again. Not that it had been put away at all…